|

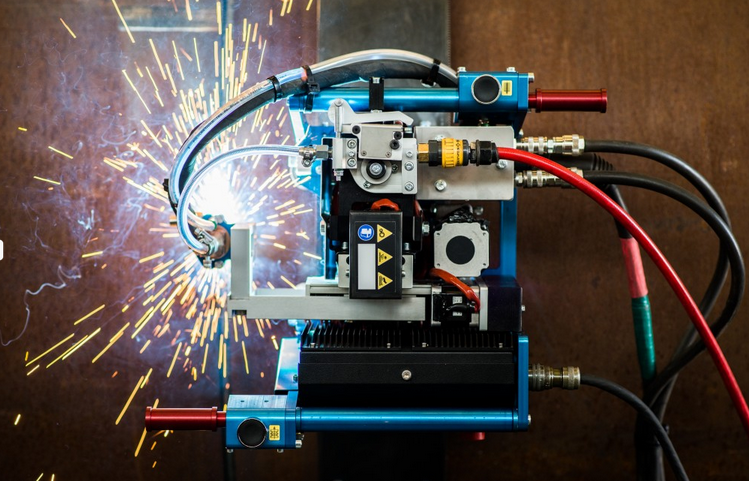

Welding processes:

- MIG

- Pulsed

- Modified short circuit RMD

Applications:

- Any steel normally welded with GMAW process;

- Any pipe diameter > 355mm (14”);

- Any thickness > 6mm;

- Solid wire, metal coreed or flux cored wire (diameter 0.8-2.0mm);

- All standard and modified bevels.

Welding parameters maximum range:

- Current =Max 400

A;

- Voltage =Max 35 V;

- Welding speed =Max 160 cm/min;

- Wire Feed Speed =Max 16 m/min;

- Oscillation Speed =Max 3.2 m/min;

- Oscillation Width =Max 32 mm;

- Dwell time =Max 3.2 sec.

DWS.03 MAIN FEATURES

- All the welding passes are performed

from the outside;

- Diameter from 14” and above, only

changing the guide band;

- Using optimum parameters for each

angular section of the joint thanks to its specific patent;

- All welding parameters are

continuously monitored, regulated and logged from the electronic

control;

- Maximum flexibility during site

operations, (each welding unit can perform all the passes);

- Digital record of all the parameters;

- Perfect operation guaranteed from

-40°C to +60°C;

- Easy training and very low

intervention of the operator;

- Easy to install on all types of track

or wheel tractors.

|